Total Cost of Ownership (TCO) is the full lifecycle cost of industrial equipment, including the cost to buy, operate, maintain, and eventually replace it. For air compressors and chillers, TCO is driven far more by ongoing energy and operating costs than by the initial purchase price.

Main Cost Drivers to Know:

- Electricity or energy consumption

- Maintenance and consumables (filters, oil, water treatment, spares)

- Downtime and performance losses (pressure drops, poor cooling, breakdowns)

So how do these individual cost drivers come together over the life of the equipment? The answer lies in Total Cost of Ownership.

Buyers should care because the “cheapest” machine on Day 1 can become the most expensive one once energy bills and lost production stack up.

In this post, we’ll break down the TCO of two critical industrial systems, air compressors and chillers, to help you uncover hidden costs and optimize your bottom line.

But first, let’s quickly look at a real-world story that highlights the importance of keeping TCO in mind while procuring any heavy machinery for a factory.

The Story of a Costly Miscalculation in a Factory

Ramesh, the operations manager of a mid-sized textile factory in Gujarat, was under pressure. His company needed to upgrade its air compressors before peak production season. With tight budgets, he chose the cheapest model available in the market, convinced that he was making a financially sound decision.

For a while, things seemed fine. But within a few months, the electricity bills shot up. Workers started complaining about pressure drops, which slowed production. Routine maintenance turned into costly emergency repairs, and worst of all, downtime losses exceeded ₹10 lakh in just a year.

Ramesh had fallen into a common trap: focusing on upfront cost instead of TCO. If he had invested in a higher-efficiency air compressor, he could have saved on energy costs, reduced breakdowns, and ensured smooth operations, ultimately saving the company money in the long run.

His story isn’t unique. Many Indian industries, whether in textiles, pharmaceuticals, food processing, or heavy manufacturing, face similar challenges.

Let’s break down how TCO impacts air compressors and chillers, and how businesses can make smarter investment decisions.

How to calculate Total Cost of Ownership (TCO) for air compressors and chillers

Total Cost of Ownership (TCO) represents the complete lifecycle cost of industrial equipment, going far beyond the initial purchase price. A practical way to estimate TCO is to account for every major cost incurred from installation to end-of-life.

TCO = Capital Cost + Energy Cost + Maintenance & Repairs + Downtime Losses + Consumables + End-of-Life Costs

Here’s how each component contributes to overall TCO:

| Cost Component | Description |

|---|---|

| Capital Cost (CapEx) | The upfront cost of purchasing and installing the compressor or chiller, including site preparation, piping, electrical work, and commissioning. |

| Energy Cost | Electricity consumed during operation over the equipment’s lifetime, typically the largest contributor to TCO for both compressors and chillers. |

| Maintenance & Repair Costs | Planned servicing, spare parts, oil and filter replacements, unplanned breakdowns, and corrective maintenance. |

| Downtime & Productivity Losses | The financial impact of production stoppages, reduced throughput, or quality losses when equipment underperforms or fails. |

| Consumables | Recurring inputs such as lubricants, coolants, water treatment chemicals, desiccants, seals, and filters. |

| End-of-Life Costs | Decommissioning, disposal, recycling, and environmental compliance costs once the asset reaches the end of its useful life. |

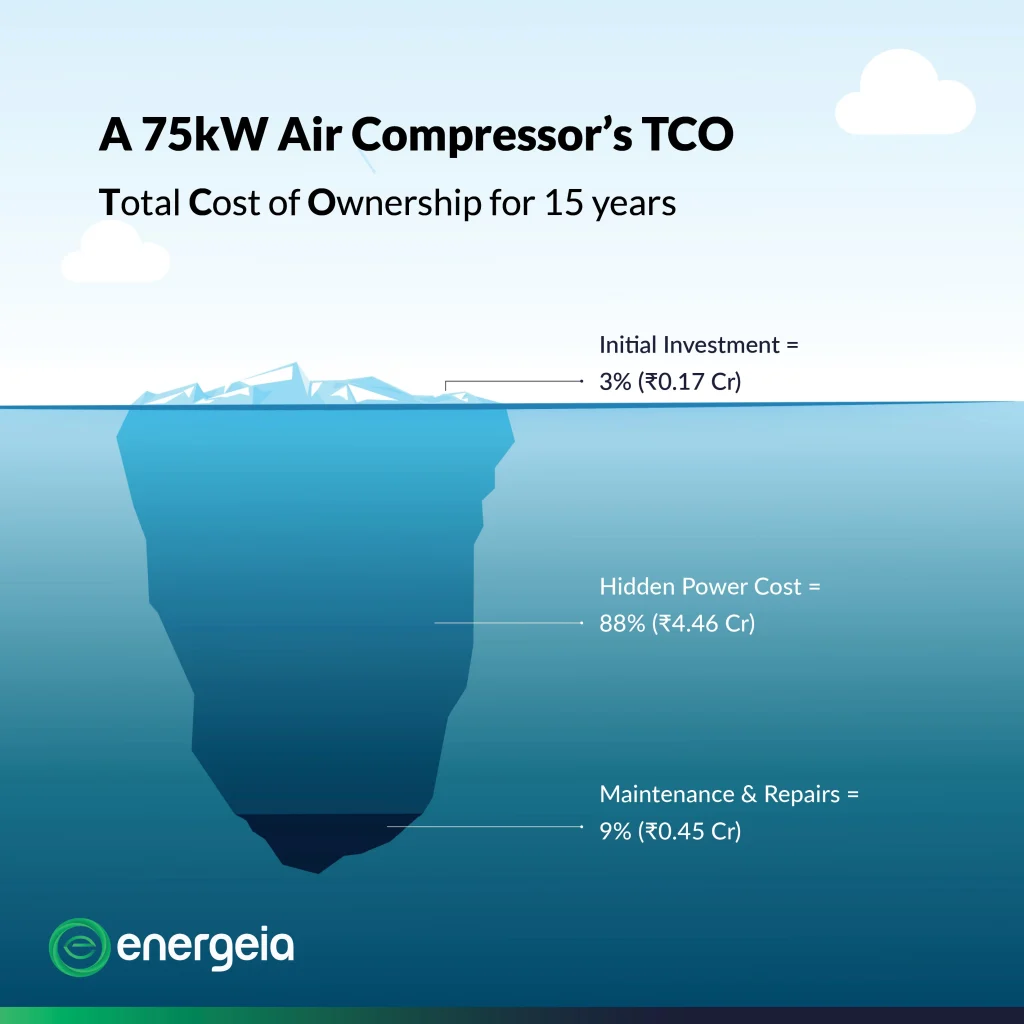

TCO for Industrial Air Compressors

Air Compressors: Total Cost Insights

| Type of Cost | Description | Typical Contribution to TCO |

| Initial Investment | Compressor purchase, installation, piping, electrical setup | 2-10% |

| Hidden Power Cost | Power usage (kWh/year), efficiency rating (CFM/kW) | 65-90% |

| Maintenance & Repairs | Routine servicing, parts replacement, moisture removal, filtration | 5-10% |

- Energy costs dominate – 80% of total ownership costs come from electricity consumption.

- Compressed air leaks = wasted money – Up to 20% of generated air is lost through leaks.

- Predictive maintenance reduces costs – IoT-based monitoring can cut downtime and repair expenses by 25%.

Key Savings Strategies for Air Compressors

✅ Invest in high-efficiency compressors (CFM/kW optimized)

✅ Regularly check for air leaks to reduce waste

✅ As a practical rule of thumb, every ~2 psi reduction in operating pressure can lower energy consumption by about 1%

Real-world Example

Unsure of how to fund such CAPEX-heavy compressor upgrades?

We understand that it’s difficult to allocate a large budget for such expensive upgrades. That’s why Energeia offers multiple flexible financing models to make sure you can reduce your energy and equipment costs without straining your cashflow.

Read about how our unique pay-as-you-save model enabled a Metal Manufacturer in NCR to cut annual energy costs by 37% with zero upfront investment.

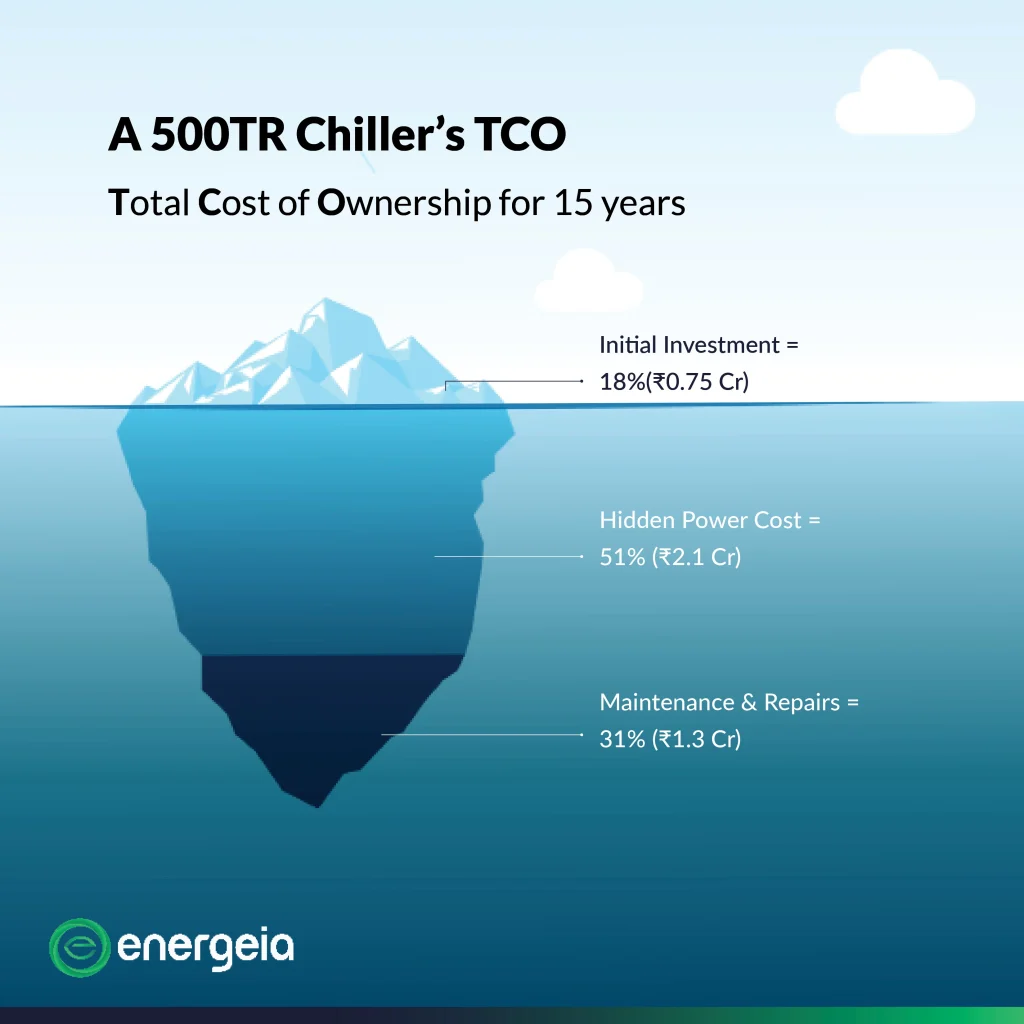

TCO for Industrial Chillers

Chillers: Total Cost Insights

| Type of Cost | Description | Typical Contribution to TCO |

| Initial Investment | Chiller purchase, installation, piping, electrical setup | 2-20% |

| Hidden Power Cost | Power usage (kWh/year), efficiency (COP/EER) | 50-70% |

| Maintenance & Repairs | Servicing, parts replacement (fans, coils, pumps, filters), water and chemical use | 25-35% |

- Energy is the biggest expense – 50-70% of TCO comes from invisible power consumption.

- Water-cooled vs. air-cooled? – Water-cooled chillers are more efficient but have higher maintenance & water treatment costs.

- Downtime is expensive – Predictive analytics reduces failures by 20%, preventing costly production halts.

Key Savings Strategies for Industrial Chillers

✅ Choose high COP/EER chillers to improve efficiency

✅ Implement demand-based cooling controls to optimize power use

✅ Regularly maintain cooling towers and water treatment systems

Real-world Example

Final Thoughts

Invest Smart, Save Big

When it comes to industrial equipment, the purchase price is often treated as the deciding factor. But as we’ve seen with air compressors and chillers, the sticker price is only the tip of the iceberg.

The real cost of owning and operating industrial machinery unfolds over its entire lifecycle. Energy consumption, maintenance, unplanned downtime, and end-of-life expenses can quietly add up to crores in hidden costs, often far exceeding the initial capital investment.

This is why Total Cost of Ownership (TCO) matters. TCO captures every expense associated with an asset, from installation and energy use to repairs, productivity losses, and eventual disposal. Businesses that ignore TCO often find themselves stuck with rising energy bills, frequent breakdowns, and avoidable production losses, eroding margins year after year.

On the other hand, organizations that adopt a TCO-driven approach make smarter, future-ready decisions. Investing in energy-efficient equipment, predictive maintenance strategies, and real-time energy monitoring not only reduces operating costs but also improves reliability, sustainability, and long-term financial performance.

👉 Are you looking to reduce your industrial equipment’s costs? We can build a custom TCO analysis for your industrial machinery to help you maximize your cost savings and minimize your emissions.

Consult with Energeia today to take the first step toward smarter investment decisions for tomorrow.

📞 Book a Complimentary Energy Appraisal Today: +91 9319271849