Consulting

Turn those ambitious net zero pledges into real action without the steep learning curve

Talk to a Consultant

Trusted by Industry Leaders

Power Your Future with Proven Expertise

Personalized Consulting for Your Unique Needs

The pressure to meet ESG and net-zero goals is real. We empower teams to plan, implement and meet these targets.

BEE - Accredited ESCO

Partner with a team recognized for excellence in energy services, meeting the highest industry benchmarks for performance and reliability.

IPMVP Auditors

Our qualified auditors analyze your data to build performance benchmarks and find the gaps.

Savings Simulator

Our energy monitoring platform predicts how much you can save with every change you make.

ESG & Compliance

We ensure you’re ahead of the newest government rules and ESG reporting standards.

OUR OFFERINGS

- Implementation

- Financial Consulting

- Compliance

- Renewables

- Capacity Building

Engineering & Design Solutions

We help retrofit old setups or design brand new ones. Think HVAC layouts, motor upgrades, and system optimizations.

Technology Deployment

Source and deploy the latest, energy-efficient hardware and software that make energy waste a thing of the past.

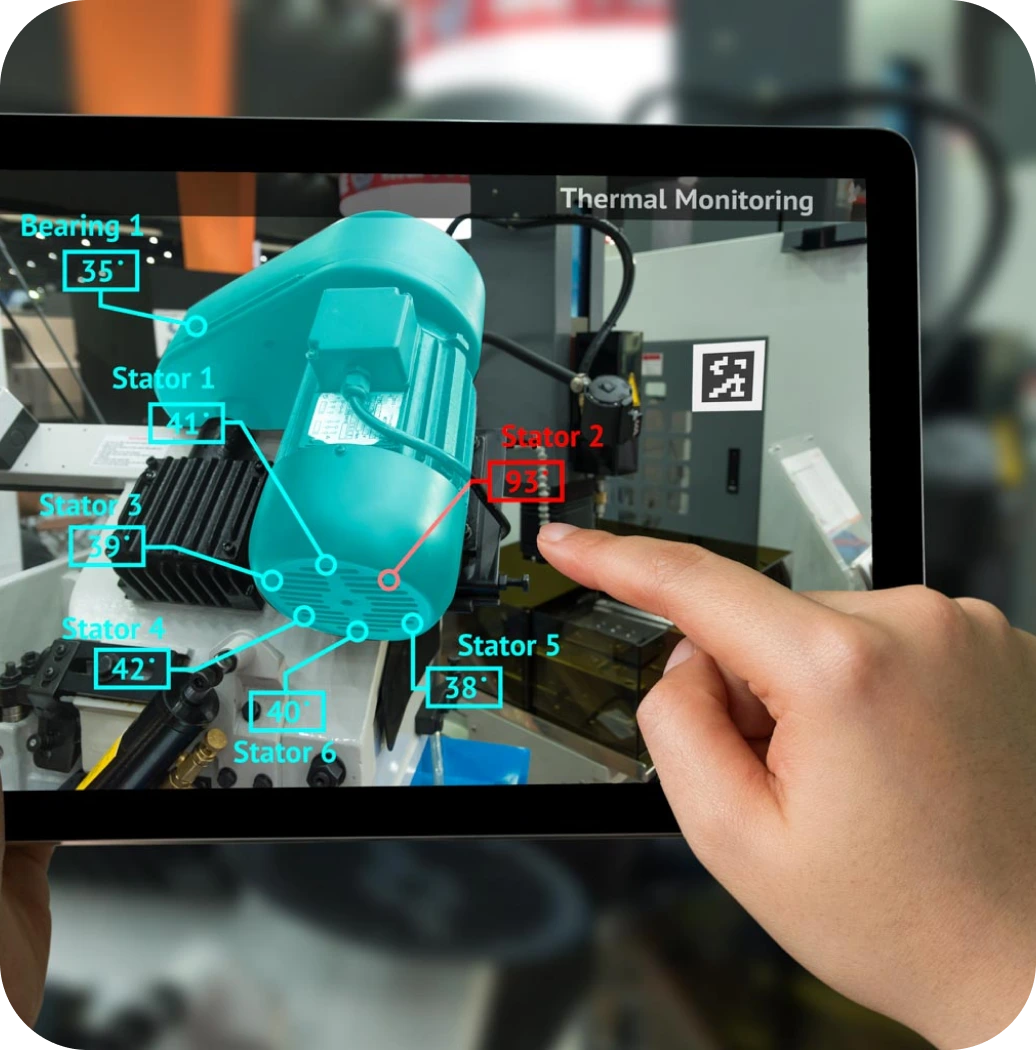

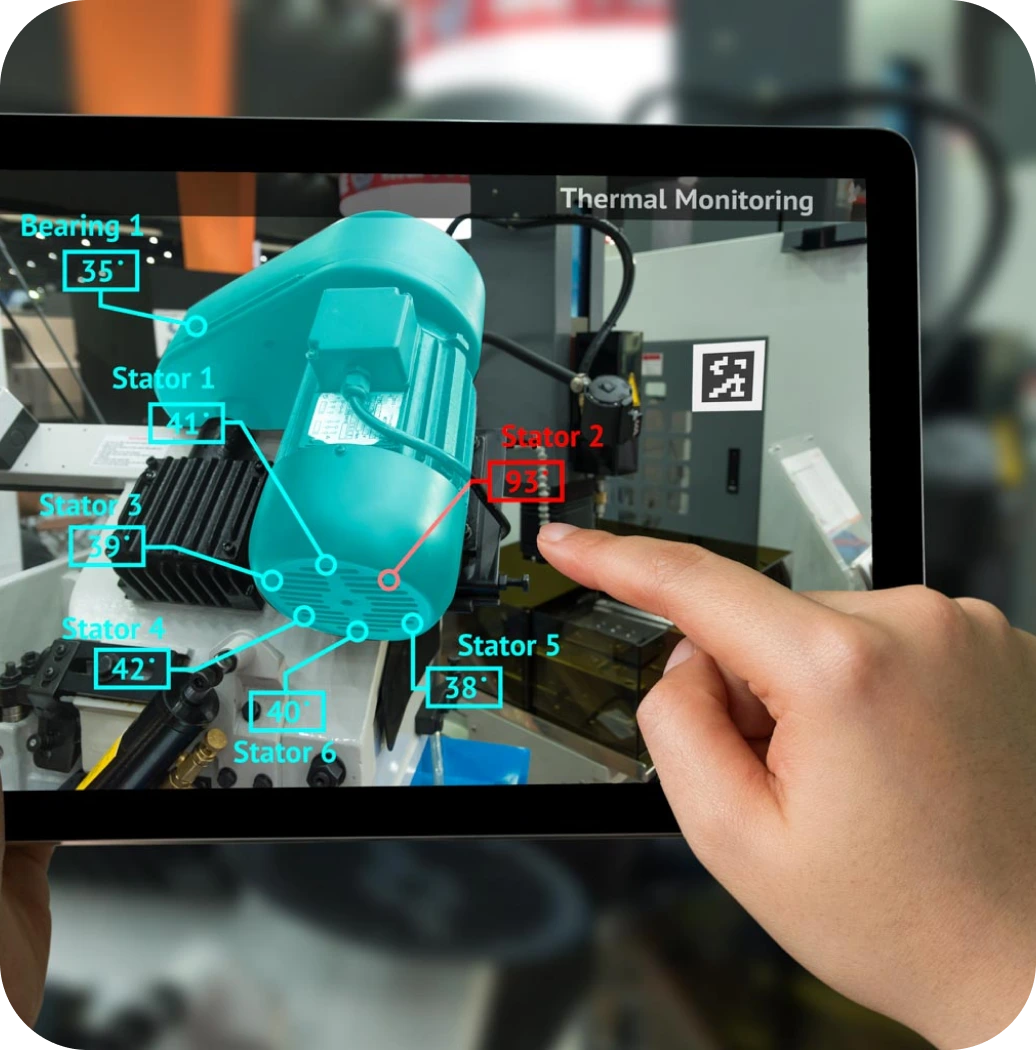

Real-Time Monitoring Solutions

Stay on top of your energy game with IoT systems that track usage in real-time so you’re always optimizing, never guessing.

Remote ESG Consultant

Get expert advice, wherever you are. We guide you remotely to make sure your systems run smoothly, no matter the distance.

SCADA System Analytics

Turn your SCADA data into gold. We analyze it to fine-tune your operations for maximum compliance and efficiency.

Measurement & Verification

We don’t just measure success—we verify it. Our M&V techniques ensure you see real, measurable savings from every project.

Cost-Benefit Analysis

We break down the numbers, so you see exactly how much you stand to gain from energy efficiency projects.

Incentive & Subsidy Navigation

Money on the table? We’ll help you grab it, guiding you through the maze of grants, subsidies, and incentives.

Decoding Government Regulations

Regulations are always changing. We make sure you’re not just compliant but ahead of the game, reducing risk and boosting credibility.

Sustainability Roadmapping

We help you build a 5-year sustainability plan that cuts emissions, reduces waste, and positions you as an industry leader.

ESG Reporting

Tell your green story with data to back it up. We help you create reports that showcase environmental stewardship.

Renewable Energy Strategy and Planning

We turn your renewable ambitions into reality, whether it’s solar, wind, or something new. Reduce grid reliance, one kilowatt at a time.

Energy Storage Systems

Don’t just generate energy—store it. Keep your operations running smoothly, even when the sun doesn’t shine or the wind doesn’t blow.

Technical & Operational Training

Equip your team with the know-how to keep new systems running at peak efficiency from day one, and handle anything.

Energy Management Workshops

Foster a culture of energy efficiency with workshops that turn conservation into a competitive advantage for your business.

Ready to Elevate Your Energy Strategy? Let’s Talk

Related Services from Energeia

Air Compressor Optimization (E-Air)

An end-to-end solution designed to unlock cost savings in your industrial air compressors at zero upfront cost.

Chiller Optimization (E-Chill)

An end-to-end solution that delivers energy savings in your HVAC systems with minimal investment.

Process Heat Optimization (E-Heat)

An end-to-end solution that reduces energy waste in your boilers and furnaces with minimal investment.

Energy Audits

Explore more opportunities for sustainability and cost reduction with our customized energy audit services.