Understand Your Energy

Data in Real-Time

An Intelligent IoT Energy Monitoring System (EMS) built specially for industries and commercial facilities

Trusted by Industry Leaders

Our Approach

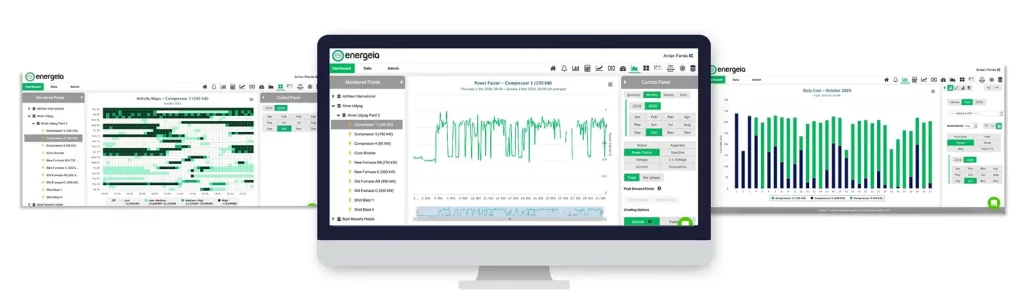

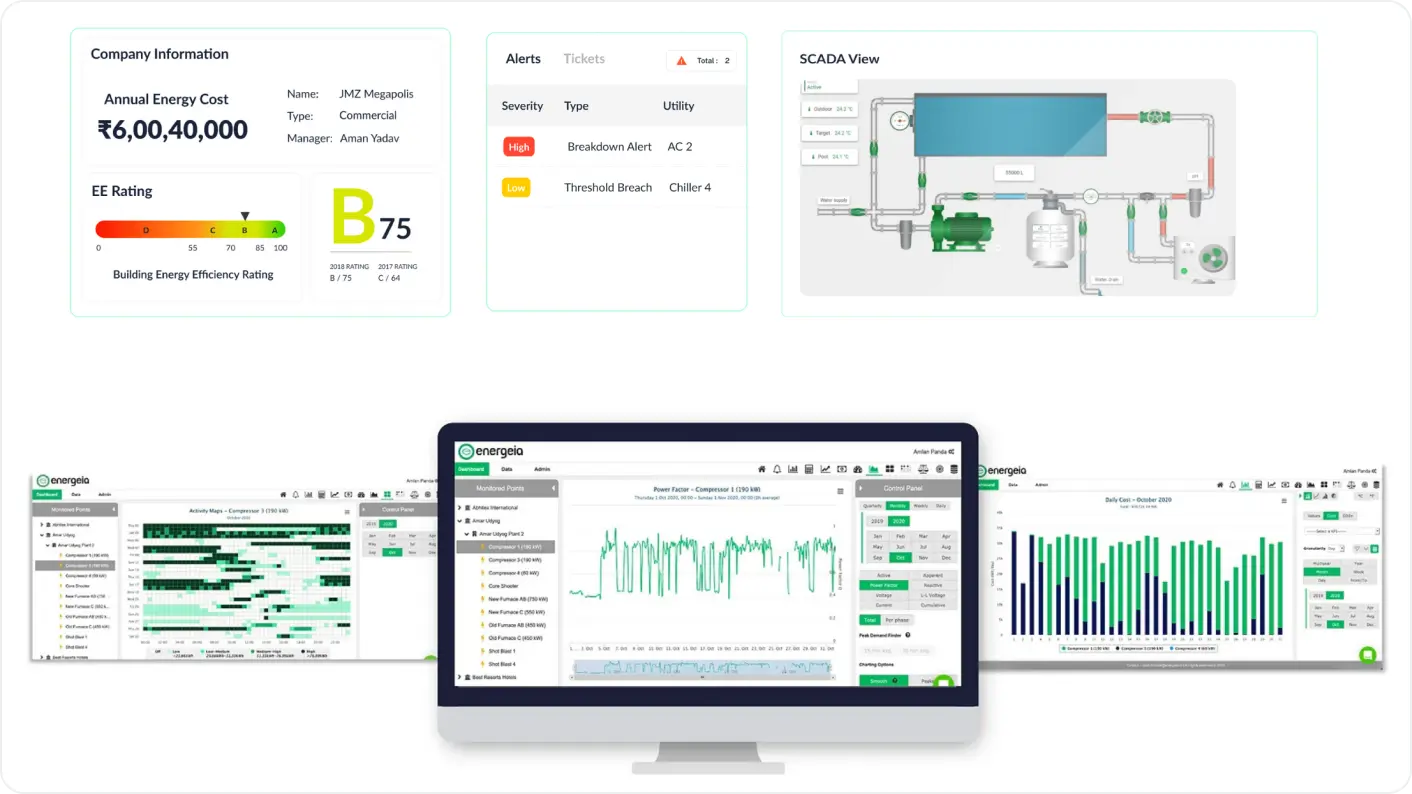

Discover the Power of Energeia’s EMS

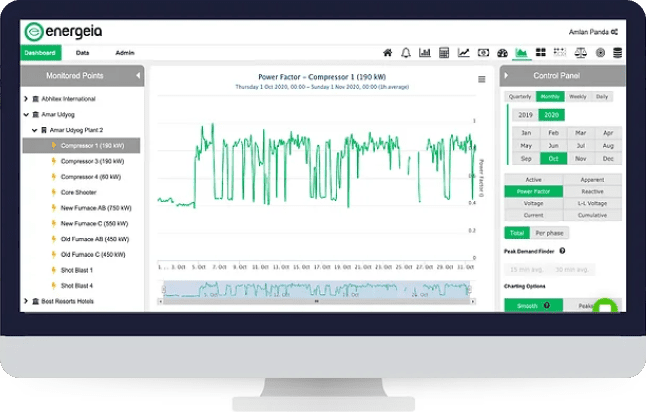

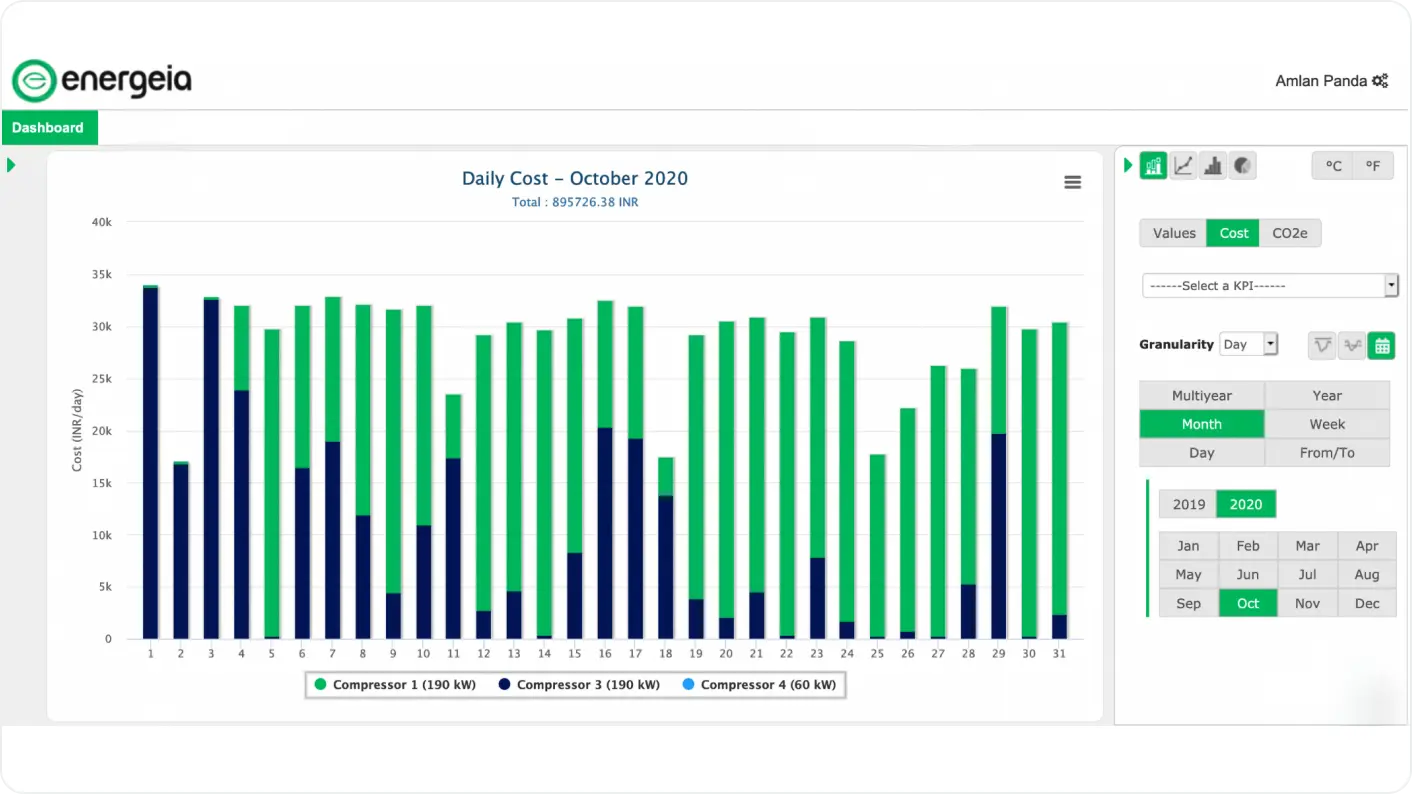

Real-time Monitoring

Real-time Monitoring

Visualize real-time energy and resource flows—diesel, gas, air, steam, water, and heat—to analyze usage and establish benchmarks for specific energy consumption.

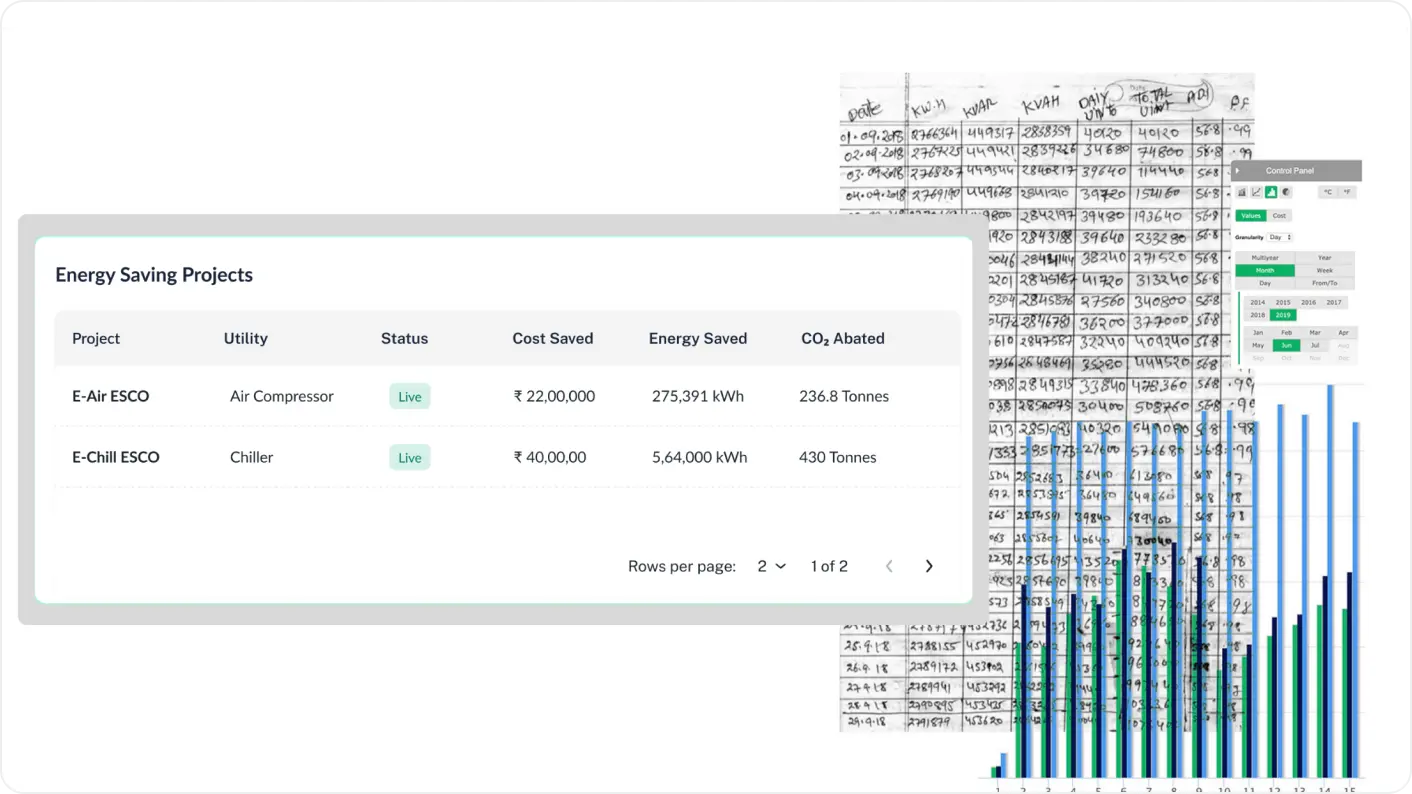

Actionable M&V

Actionable M&V

Ditch the endless spreadsheets to justify your efficiency investments. Our EMS delivers undeniable proof of savings, and is built keeping IPMVP and ISO 50001 in mind.

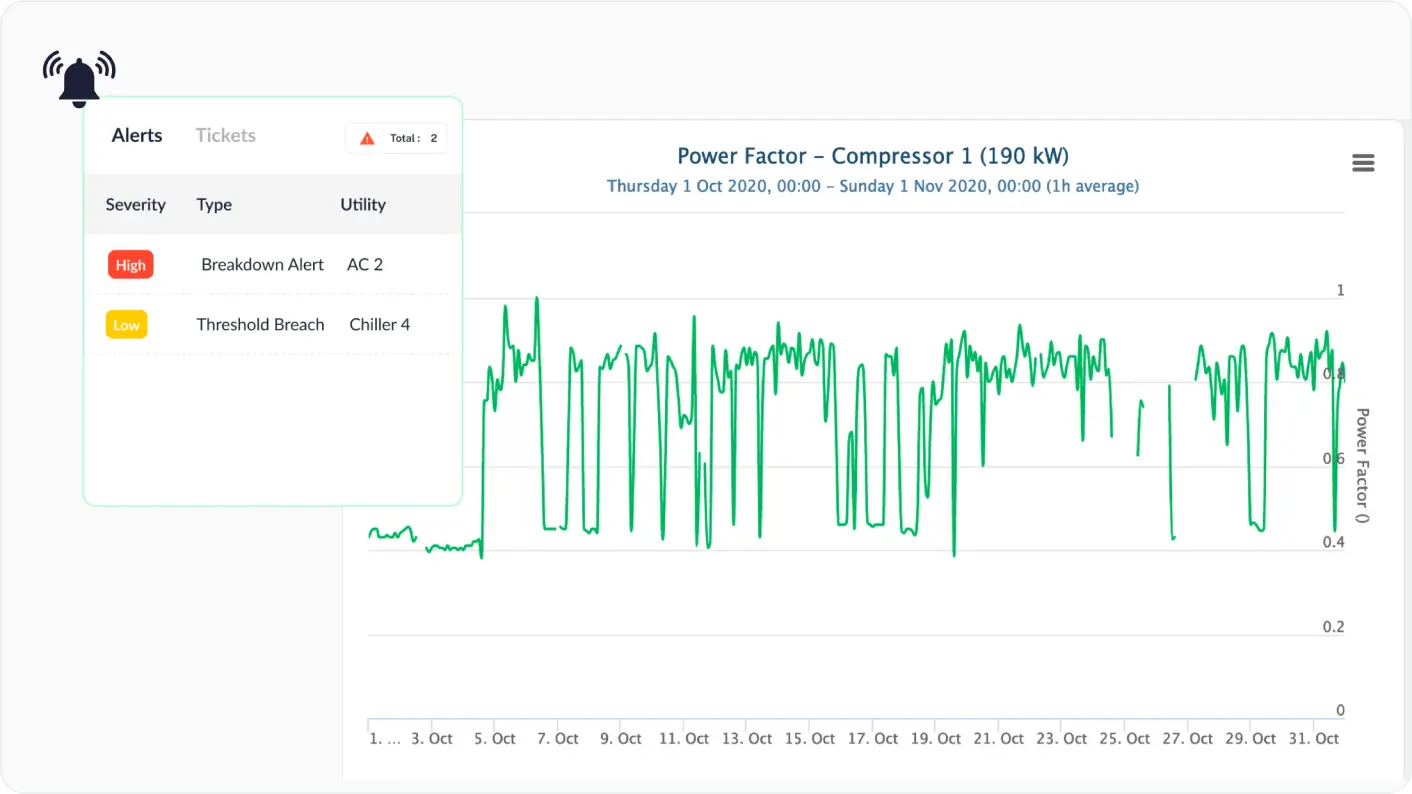

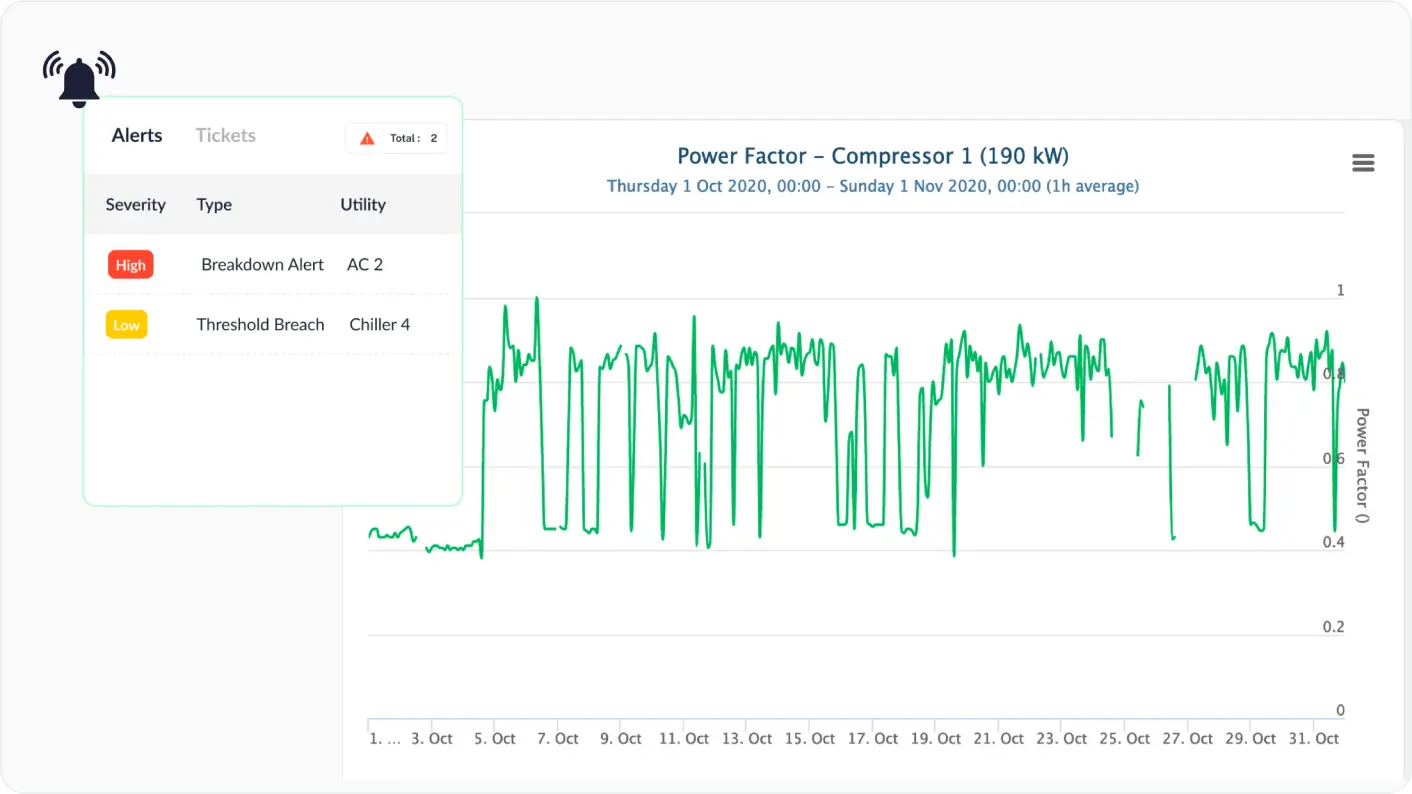

Smart Alerts

Smart Alerts

Set custom alerts for instant notifications about unusual energy spikes or alarming inefficiencies, enabling prompt action and preventive maintenance to minimize downtime.

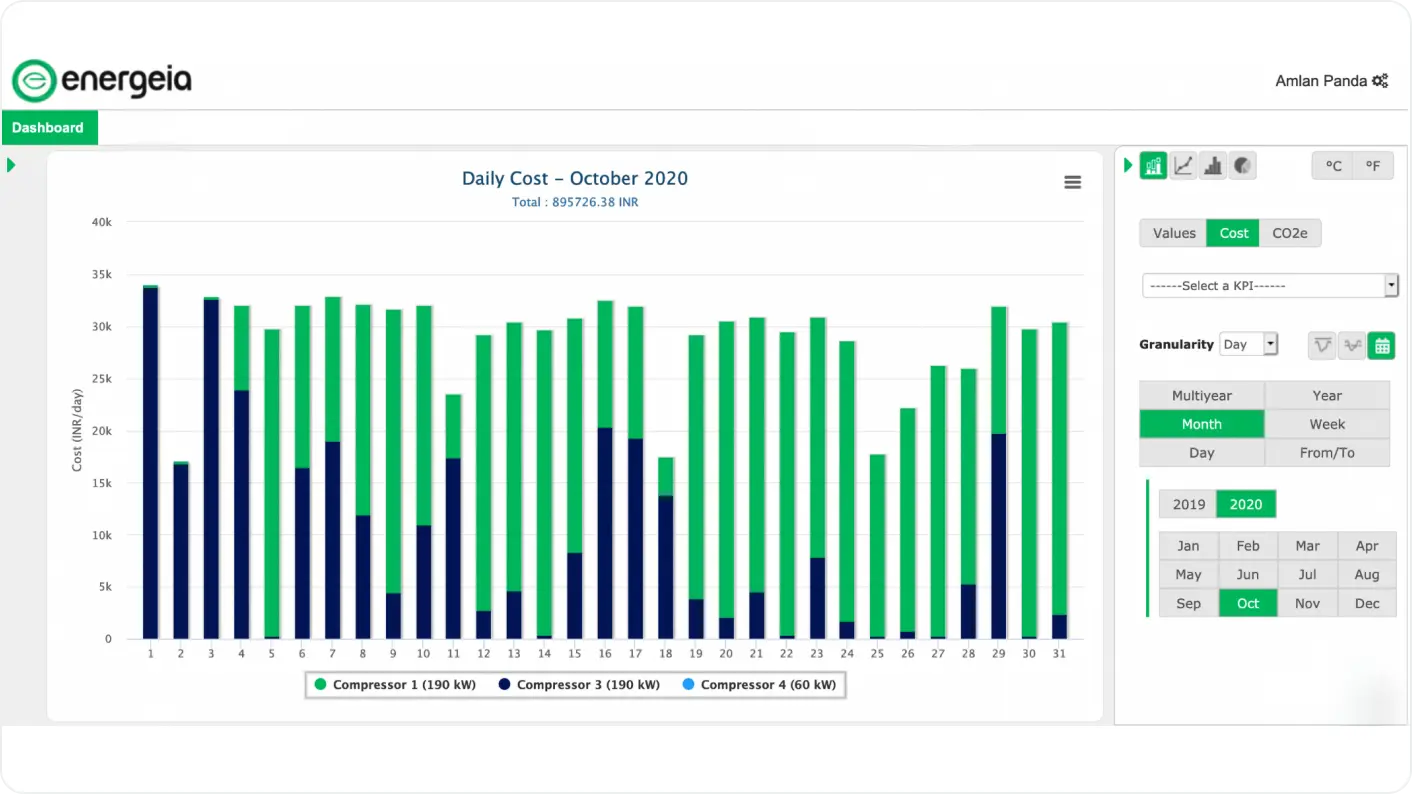

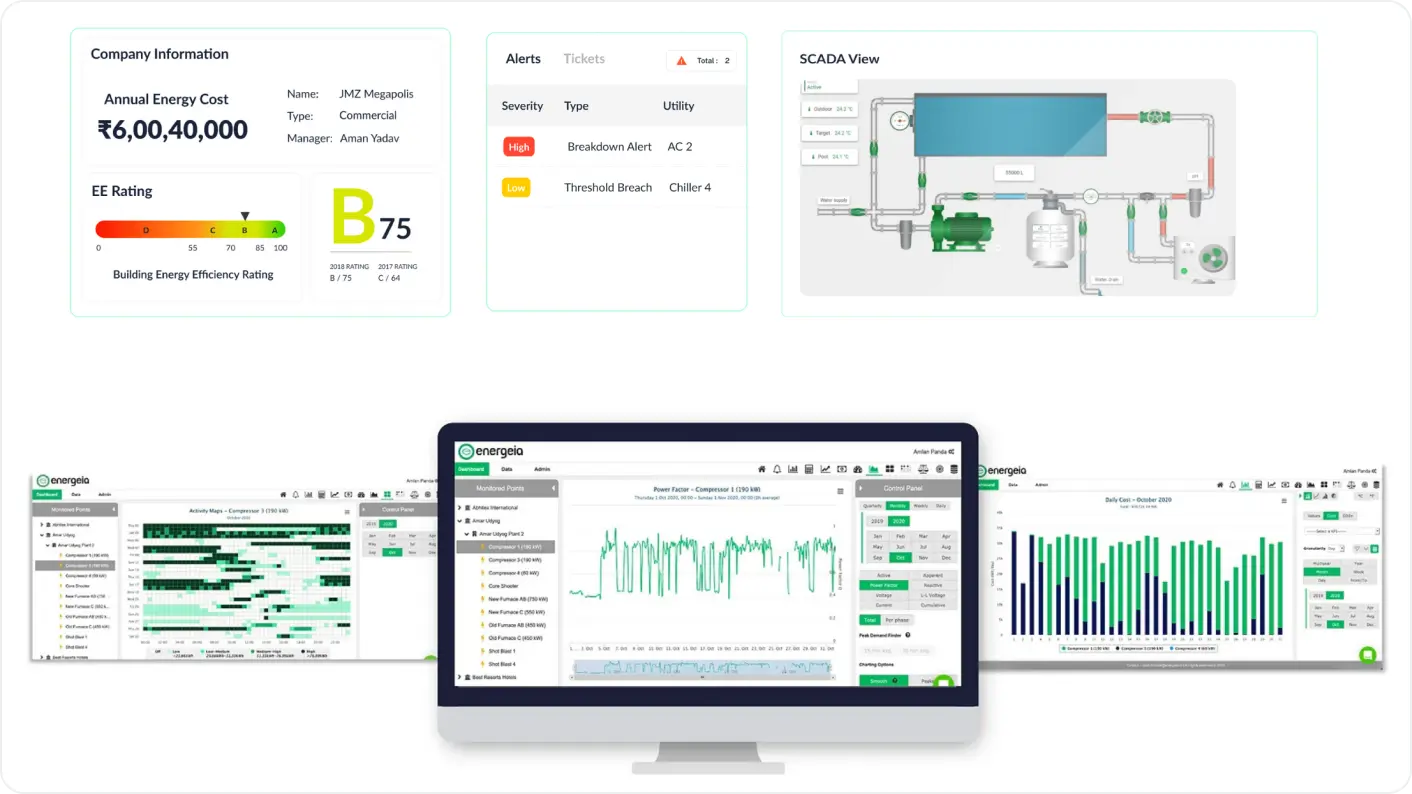

Customizable Dashboards

Customizable Dashboards

Replace manual analysis with advanced analytics that automatically prioritize key insights, while allowing you to personalize dashboards to focus on your most important metrics.

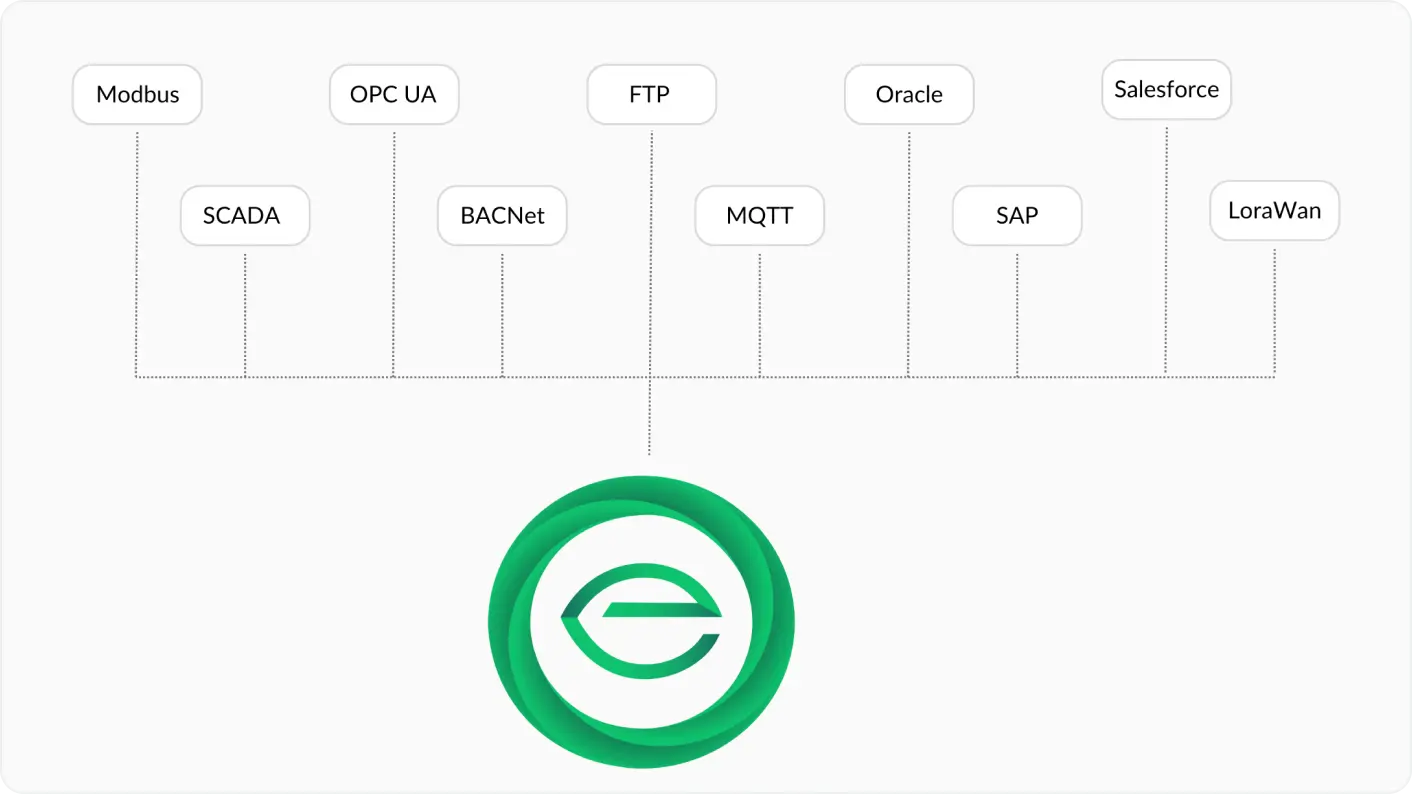

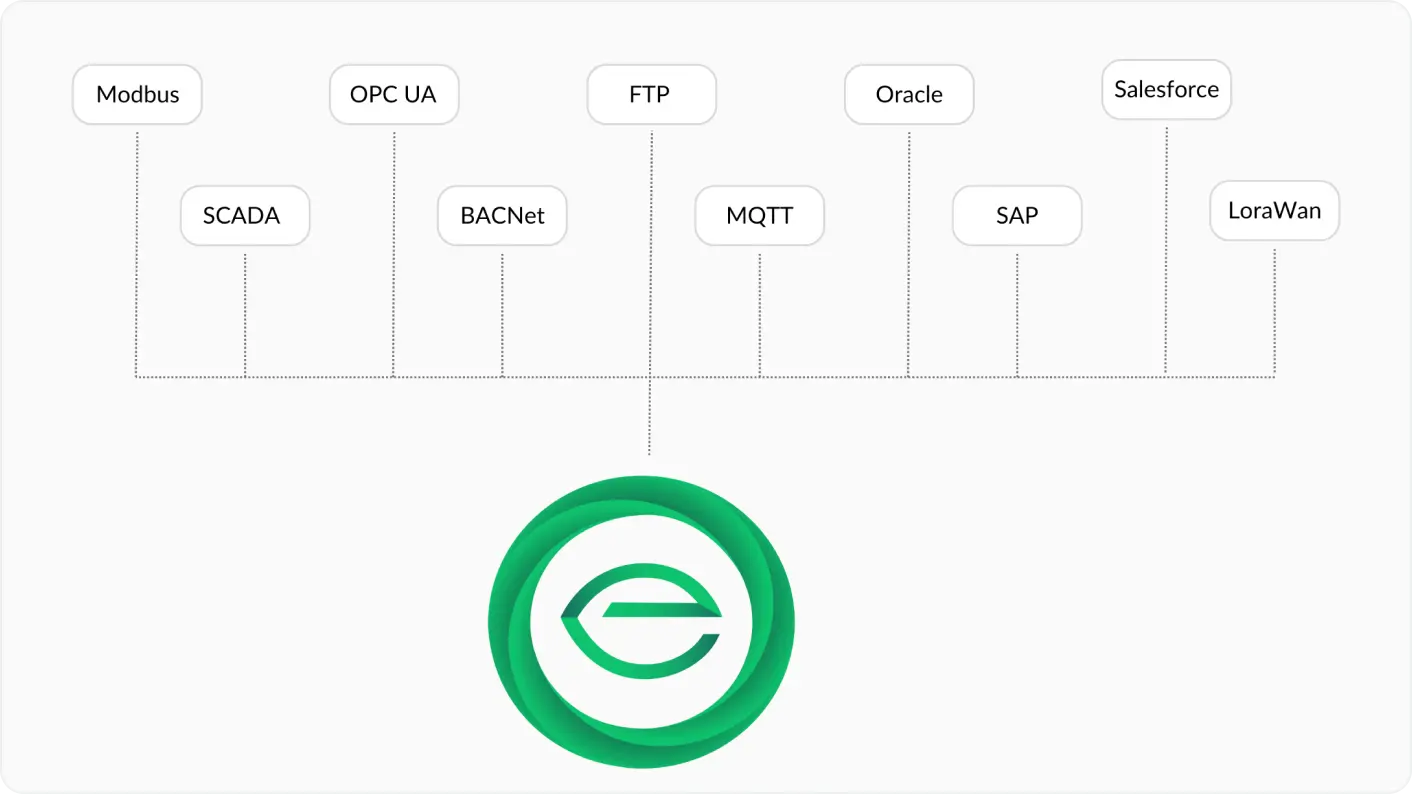

Effortless Integration

Effortless Integration

Our EMS platform aggregates raw data from high-quality sensors across multiple machines, delivering precise insights for your entire facility’s energy infrastructure.

Visualize real-time energy and resource flows—diesel, gas, air, steam, water, and heat—to analyze usage and establish benchmarks for specific energy consumption.

Ditch the endless spreadsheets to justify your efficiency investments. Our EMS delivers undeniable proof of savings, and is built keeping IPMVP and ISO 50001 in mind.

Set custom alerts for instant notifications about unusual energy spikes or alarming inefficiencies, enabling prompt action and preventive maintenance to minimize downtime.

Replace manual analysis with advanced analytics that automatically prioritize key insights, while allowing you to personalize dashboards to focus on your most important metrics.

Our EMS platform aggregates raw data from high-quality sensors across multiple machines, delivering precise insights for your entire facility’s energy infrastructure.

Visualize real-time energy and resource flows—diesel, gas, air, steam, water, and heat—to analyze usage and establish benchmarks for specific energy consumption.

Value Proposition

Energeia's EMS vs. The Competition

Experience the Future of Smart Energy Monitoring

| Feature | Energeia’s EMS | Other EMS in the Market |

|---|---|---|

EMS End-Use Applications

Predictive Maintenance

Prevent downtime, prolong equipment life with our predictive maintenance solutions detecting issues early.

Energy Accounting

Create automated reports related to utility, energy, and emissions tracking to comply with ISO50001, LEED, and EU ETS.

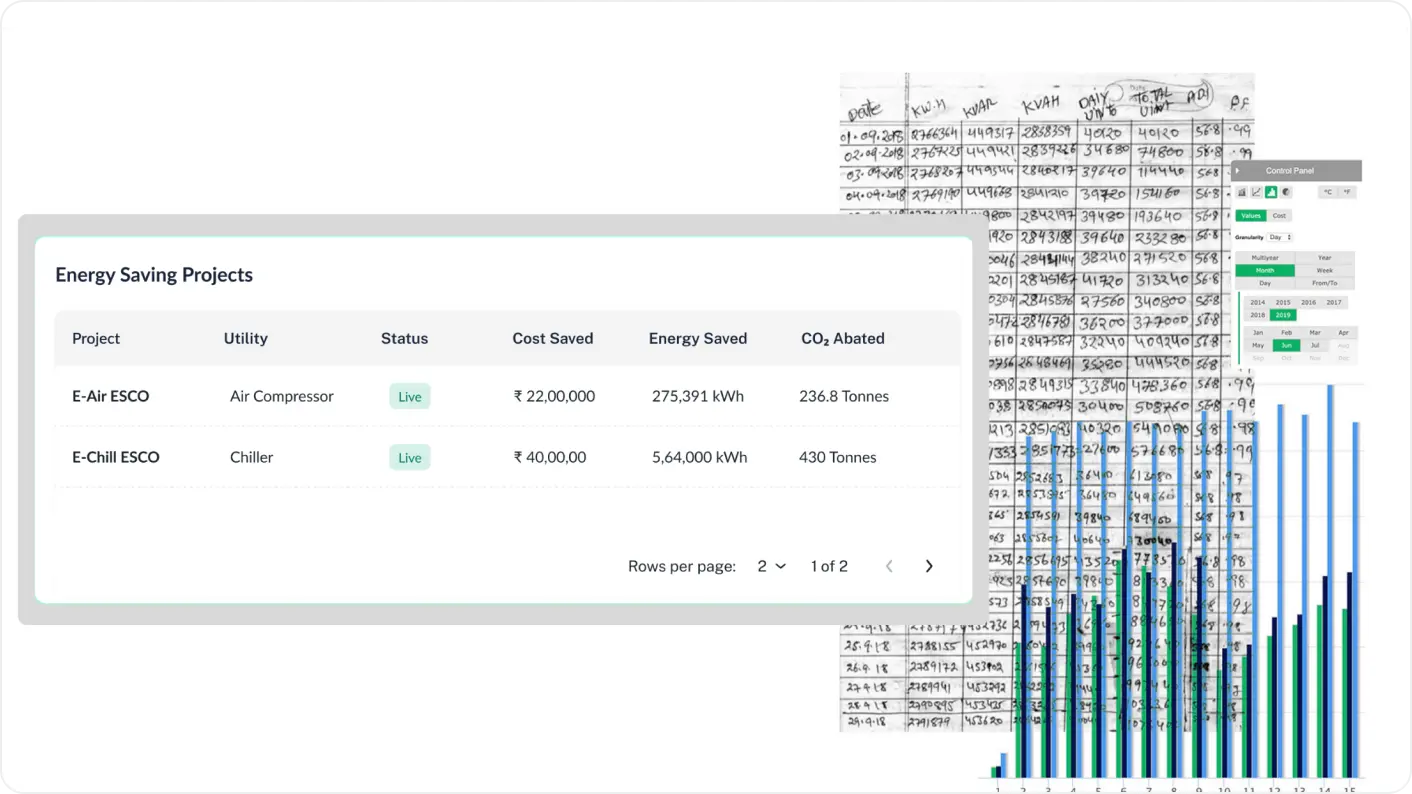

Savings Tracking

Track and measure how much energy you’re saving with every energy efficiency upgrade or retrofit solution.

See Energeia’s EMS in Action

Related Services from Energeia

Chiller Optimization (E-Chill)

ptimize your cooling processes, save energy, improve performance, and extend equipment life.

Process Heat Optimization (E-Heat)

Enhance your heating systems,reduce energy waste, and cut costs with our solutions.

Energy Audits

Find opportunities for sustainability and cost reduction with our energy audit services.

Sustainability Consulting

Gain much-needed market expertise with end-to-end consulting services to reduce costs and lower waste.