Executive Summary

From Blind‑Spot Risk to Data‑Driven Control

The Plant Head, Mr. Arjun Pandey, oversees a leading forging and manufacturing facility, where the production floor runs on more than just machines — it runs on pressure, power, and precise timing.

We always knew the machines were working. But were they working efficiently? Were we bleeding energy without knowing? Frankly, we were operating on gut feeling more than data,” recalls Mr. Pandey.

Monthly energy bills told an unsettling story: unexplained kWh spikes, voltage‑related breakdowns, and compressors idling unseen. With no live dashboard, the team could only react—never prevent.

It became clear: they weren’t just battling inefficiency; they were fighting blind spots.

That’s when the plant partnered with Energeia to replace guesswork with real‑time insight using our EMS.

Key Stats

Daily Datapoints Analyzed

Execution Time

Monitored

Customer Overview

Inside a Heat‑Intensive Forging & Machining Plant

- Industry: Precision forging & machining

- Location: Greater Noida, India

- Facility: 58 critical machines in 8 areas (Forge Shop, Machine Shop, Induction Billet Heater, Cutting Shop, Compressors, DG set, Power Distribution, Transformers)

- Load Profile: 12-hour shifts, heat-intensive, power-quality-sensitive

The facility operates a range of high-load equipment, including forging lines, CNC machines, and heat treatment units. With energy-intensive operations spread across multiple processes, the facility was looking for a solution to improve energy visibility, load-specific monitoring, and process-wise consumption tracking to drive operational efficiency.

The Challenge

The Invisible Blind Spots Costing Lakhs

Before Energeia’s Energy Monitoring System (EMS) deployment, the factory’s operations team was dealing with critical visibility gaps that led to inefficiencies, downtime risks, and rising operational costs.

- No real-time visibility: Data was paper-based, delayed, and error-prone — leaving teams guessing between checks.

- Machine-level blind spots: Operators couldn’t track whether machines were overloaded, underutilized, or causing imbalance.

- Unnoticed energy wastage: Departments operated in silos, with no unified consumption benchmarks or optimization strategies.

- Power quality risks: Voltage dips, harmonics, and phase imbalances were invisible — silently degrading equipment.

- Rising operational costs: Electricity bills climbed steadily, with no clear understanding of root causes.

- Lack of actionable data: Teams lacked the insights to justify investments or drive efficiency measures proactively.

In a high-load forging and machining environment, this lack of visibility didn’t just mean missed savings; it meant lost control over efficiency, reliability, and costs.

“Machines don’t complain until it’s too late. We needed eyes on every parameter in real time,“ said Mr. Pandey.

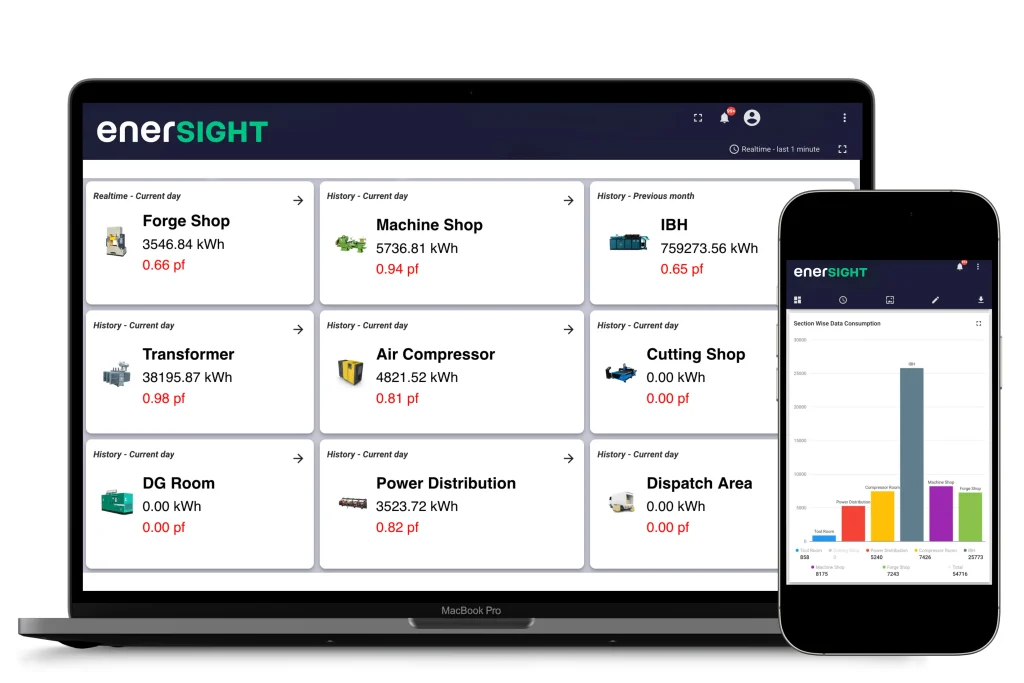

The Solution: EnerSight EMS

24/7 Energy IoT Monitoring

Energeia’s EMS was deployed across the plant with zero operational disruption and was fully commissioned within 10 days. The objective wasn’t just monitoring — it was engineering actionable visibility into every process kilowatt.

How It Was Implemented:

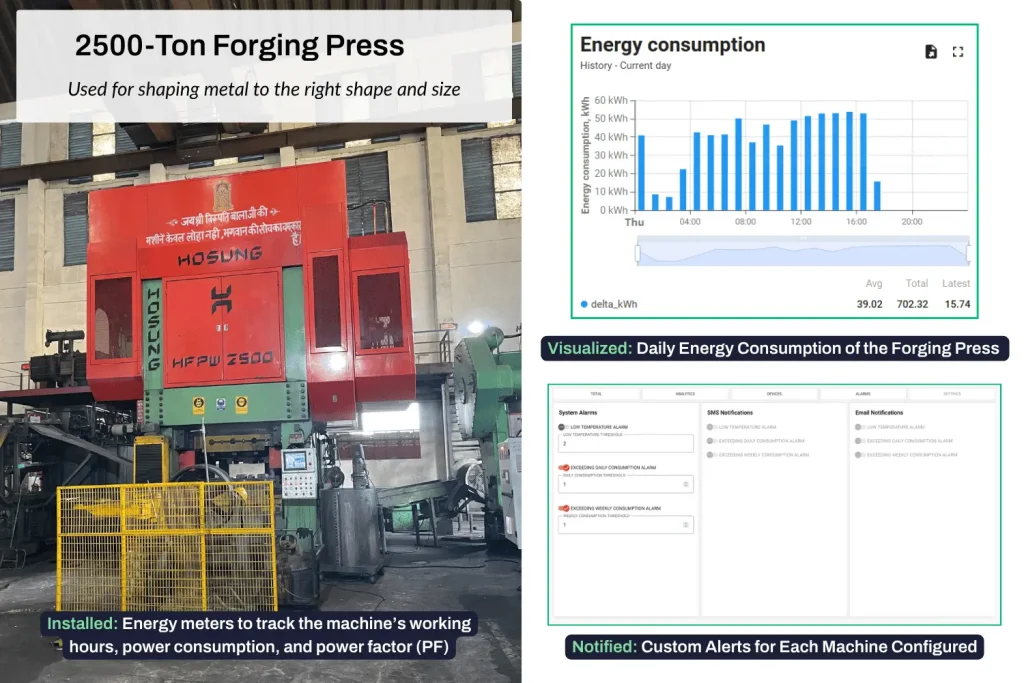

- Smart Meters: 58 IoT energy meters were installed at all critical assets like compressors, machinery, and lighting circuits.

- Security IoT Gateway: All meters were networked to a cloud-connected gateway, ensuring secure, real-time data flow from the shop floor to Energeia’s EMS platform.

- Granular Load Mapping: Consumption was mapped at both macro (plant-level) and micro (machine-level) — giving teams the ability to pinpoint exactly where, when, and why energy was being wasted.

- Auto-triggered Alarm Logic: Smart alerts were configured for deviations — whether from abnormal equipment load, voltage dips, or power factor degradation — each tagged with timestamps and statuses (active, cleared, acknowledged).

- Trend-Based Diagnostics: Interactive dashboards with time-series graphs made it easy to track patterns — like compressor inefficiencies during night shifts or recurring power dips tied to specific loads.

Key Impact

Business Results & EMS Benefits in the First 30 Days

| Impact Area | Result |

| 👉 Operational Visibility | Unified view of 58 critical assets with 768 datapoints/day for faster, smarter decisions. |

| 👉 Energy Savings | Reduced compressor idling, balanced machine loads, and eliminated unnecessary runtime. |

| 👉 Power Stability | Real-time alerts prevented downtime linked to harmonics, dips, and voltage imbalances. |

| 👉 Cost Reduction | Data-backed operational changes curbed rising energy costs sustainably. |

| 👉 Asset Reliability | Reduced load stress extended compressor and equipment lifespan. |

| 👉 Sustainability Progress | Lower energy wastage contributed directly to ESG efficiency goals. |

| 👉 Reporting Effort | From hours to < 5 minutes with one‑click export |

Conclusion

From Reactive to Predictive Factory Operations

For this forging factory, Energeia’s Energy Monitoring System wasn’t just a monitoring system — it was a transformative tool for operational ease and efficiency.

What started as a need to cut energy costs evolved into full-scale operational control.

Compressor inefficiencies were corrected. Load imbalances were identified and fixed. Power quality risks were mitigated before damage occurred.

Today, the facility operates not just with confidence — but with clarity. Every kilowatt is traceable, every anomaly is caught early, and the plant’s future feels far less uncertain.

“It’s like switching on the lights in a room we’ve worked in for years — we can finally see everything clearly,” says Mr. Pandey.

The Next Step

Implementing energy-saving retrofits at zero cost

Using deep technical analysis and regular walkthrough visits to this factory, Energeia’s BEE-certified energy analysts have already found 3+ opportunities for energy savings. What our customers love is the fact that we not only identify these gaps but also help fix them with zero capex investment from them under a special financing model known as the Shared Savings ESCO Model.

This model remains available as a low-risk path forward when the company chooses to implement the recommended upgrades. You can earn more about ESCO Models here or checkout our case study on how we saved Rs.41.25 Lakh in annual compressed air costs for a metal manufacturing factory with zero capex investment from the customer.

Ready to Spot Your Own Energy Leaks?

With a strong track record of delivering energy-savings, Energeia has completed 1500+ projects unlocking upto between 20-60% energy savings by making industrial utilities like air compressors, HVAC systems and heating equipment more energy efficient.

📞 Book a Free Energy Appraisal Today: +91 9319271849

✉️ Email: sales@energeia.in